Propagation of Yeast, Management

SKU: Yeast Propagator

Manufacturer: Centec

Application

The YeastPropagator is used to maximize yeast viability and yeast vitality. Therefore, ideal and sterile conditions for the yeast need to be created in all stages of the propagation process.

Description

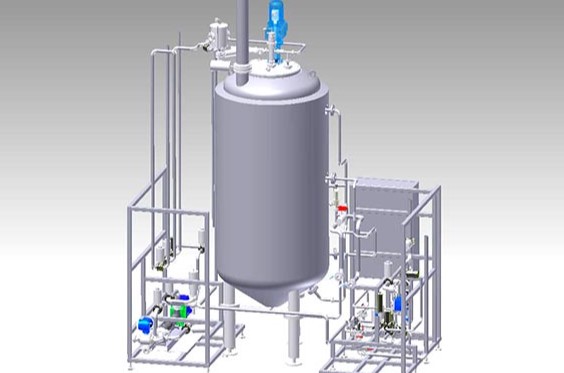

The Yeast Propagator consists of one or more individually controllable propagation tanks. The number and the size of the propagators relates to the brewery’s capacity, processes and the customer’s specific preferences. For yeast propagation the yeast suspension is filled into the propagator and mixed with fresh wort until the desired yeast quantity and cell concentration are reached. At the same time the mixture is aerated and gently recirculated to achieve homogeneity. Inside the propagator the yeast cells grow in sterile environment. For aeration oxygen or sterile air is used. The O2 content is permanently monitored using a high precision optical OXYTRANS sensor made by Centec. Centec have decades of experience in the development and manufacturing of own precision instruments for O2 control. Ideal and stable conditions inside the propagation tank result in vital and healthy yeast cells with nearly 100 % viability. The yeast cells can be pitched into the wort stream for fermentation, or they are transferred to other propagators for further yeast growth. All yeast pumps and components in the system are designed for very gentle yeast treatment, so as to fully preserve the viability and vitality of the yeast cells. The Yeast Propagator can operate continuously or in batches. As an option, the system can be equipped with a live yeast cell monitor for highly accurate in-line cell measurement.

- Maximum viability and vitality of the yeast cells

- High microbiological security at all stages of the process

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | 1 - 500 hl per propagation tank |

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Options | electropolished surfaces inside the propagator; in-line O2 measurement; live yeast cell monitor; wort sterilization |