Nitrogenation

SKU: Nitrogenator

Manufacturer: Centec

Application

Nitrogenated beers have very small bubbles and very stable foam. The Nitrogenator is designed for continuous injection of nitrogen into beer and beer-based mixed drinks. The required N2 content is exactly reached in the final product.

Description

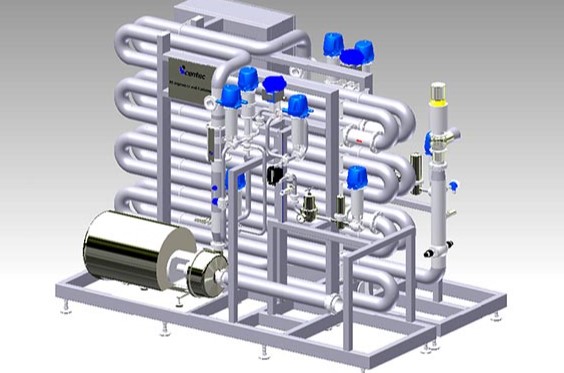

For product nitrogenation the Nitrogenator has a specifically designed Vortex-Venturi injector that feeds nitrogen in a very large number of very fine bubbles directly into the product stream. Due to high pressure and turbulent flow, the N2 dissolves completely and absolutely homogeneously in a very short time. At the end of the dissolving path a control valve is installed. This valve keeps the pressure in the system constant and above the saturation pressure. The system is equipped with high precision flow meters. Based on the measurement of the flows, the product steam and the nitrogen flow are instantly and fully automatically adjusted. Optionally, the N2 content of the nitrogenated product can be monitored by a nitrogen sensor. This sensor can be used for process control in addition to the ratio control. The desired concentration of N2 is precisely met in the nitrogenated product. The Nitrogenator is integrated into the CIP cleaning cycle of the main product line.

- High precision flow meters for process control

- Specifically designed Vortex-Venturi injector for gas injection

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | 2 - 1.500 hl/h |

| Dosing Range N2 | 5 - 60 ppm |

| Dosing Accuracy N2 | ± 1 ppm |

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Options | different automation levels; remote maintenance; access in-line N2 measurement; carbonation; buffer tank; cooling |