Orifice DP Flow with LED Display DDM EM

SKU: DDM EM

Manufacturer: Kirchner & Tochter

The device works according to the principle of differential pressure.

A tough and insensitive sensing diaphragm is embedded in the EM-transmitter housing.

download pdf datasheet

The DDM-EM measuring orifice measures and monitors the flow of gases and liquids.

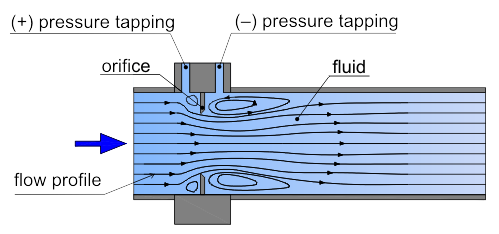

The device works according to the principle of differential pressure. A differential pressure exists on the orifice, which is proportional to the square of the volume flow through the pipeline. The user mounts the orifice between flanges or with Rp pipe unions into the conduit. The unimpeded, straight tube length has to be 6 DN before and 4 DN behind the mounting position.

A tough and insensitive sensing diaphragm is embedded in the EM-transmitter housing. By the differential pressure a spring force occurs at the measuring diaphragm. The resulting displacement is transmitted to the core of an inductive displacement transducer via an axial rod. The built-in electronics evaluates this deflection and transforms them into direct display, limit value switches and output signal.

- installation between flanges as per DIN EN 1092-1, internal and external threads as per DIN EN ISO 228 or with pipe union as per ISO 7-1

- horizontal or vertical installation

- suitable for liquids and gases

- no moving parts, wear-free

- standard measurement range or calibration according to customer specifications

- 4 – 20 mA / 0 – 10 V output

- digital LED display in m3/h

- optionally

- wall attachment installation

- limit value switches

- other display units

Operating Principle

A differential pressure arises at a pipe constriction, which is proportional to the square of the flow rate through the pipe.

The resulting differential pressure can be recorded with a meter and can be directly indicated as flow rate on a scale.