Variable Area, Flap, Side Glass

Products

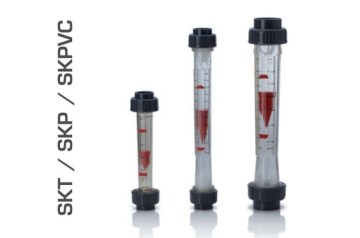

VA Flowmeter SKT/SKT/SKPVC plastic cone

Plastic Cone VA Flow Meter for cost effective Measurement The plastic flow meters SKT, SKP and SKPVC are based on the variable area float principle. The flowrate is indicated on a scale printed on the measuring tube by the indicator edge of the float. The indicator edge is identical with the largest diameter of the float. The standard scale has been designed in l/h and in % for the medium water (20 °C) and has two adjustable nominal value indications. Special scales for other substances are available on request. download pdf datasheet

VA Flowmeter SGM PP/PVC

The SGM PP/PVC VA Flow meter is a cost effective fully plastic Version - for chemical applications with highly acidic media, e.g. hydrochloric acid. Since the vertical position of the float is transmitted magnetically to a dial gauge, the SGM, as opposed to standard type variable area flow meters with a glass tube, is also suitable for measuring the flow of opaque media. Each device is individually calibrated to meet customer specifics and fitted with a medium specific scale. download pdf datasheet

VA Flowmeter SGM

VA Flow Meter for high temperature & pressure, chemical applications In all cases where a dependable device is required for indicating instantaneous values and monitoring the flow in pipelines, the SGM is the obvious choice as a reliable device for measuring the flow of liquids and gases. Since the vertical position of the float is transmitted magnetically to a dial gauge, the SGM, as opposed to standard type variable area flow meters with a glass tube, is also suitable for measuring the flow of opaque media. Each device is individually calibrated to meet customer specifics and fitted with a medium specific scale. download pdf datasheet

VA Flowmeter SGA NBR lining

VA Flow Meter with NBR-lining for acids, alkaline solutions and aggressive gases The measuring unit SGA is based on the variable area float principle. Wherever a robust and reliable device for the indication of momentary values and the monitoring of flows in pipelines is required in plant engineering, the SGA is the right choice as a reliable unit for the measurement of liquids and gases. This flow meter is available in a variety of cast iron versions for the application with various media and pressures. The measuring range for H2O is 0.012 - 0.12 m3/h to 12 - 120 m3/h, the measuring range for gas is 0.15 - 1.5 to 100 - 1000 m3/h air at STP. Each unit is calibrated to meet the requirements of the respective customer and is fitted with a scale specific for the media to be measured. download pdf datasheet

VA Flowmeter RA87/FA87 stainless steel tube

VA Flowmeter with armature completely made of stainless steel Measuring units RA 87 and FA 87 are based on the variable area float principle. In pipelines the RA 87 is installed by means of pipe unions and the FA 87 is mounted between flanges. The borosilicate glass measuring cone is located inside a protective stainless steel tube with an inspection window. All parts in contact with the measured medium are made of stainless steel 1.4571. VA flow meters RA 87 and FA 87 are most suitable for the flow measurement of transparent liquids and gases. Each unit is customized with a scale specific for the medium to be measured. RA 87 and FA 87 are mainly used in the chemical industry, in water treatment plants, in the food industry, and in other plant engineering applications. By installation of electrical limit value switches, which are adjustable throughout the entire measuring range, this devices can be used as detectors. By installing an linear displacement sensor an output signal can be generated which is proportional to the height setting of the flow meter. download pdf datasheet

VA Flowmeter RA77/FA77 plastic tube - glass cone

VA Flowmeter with plastic armature and borosilicate glass measuring cone Measuring units RA 77 and FA 77 are based on the variable area float principle. The flow meter consist of a PVC armature with a measuring cone made of borosilicate glass. With these design features the RA 77 / FA 77 devices combine the advantages of the classical VA flow meters with those of pure plastic measuring devices: Cost-effective, resistant against almost all aggressive media, as well as a high accuracy of the measuring glass, which can be calibrated to suit any requirement. Especially with water and aggressive media this design has proven itself. Therefore the RA 77 / FA 77 are frequently used in the chemical industry and in water treatment plants. By installation of electrical limit value switches, which are adjustable throughout the entire measuring range, this devices can be used as detectors. download pdf datasheet

VA Flowmeter RA65/FA65 protective steel tube

VA Flow Meter with protective steel tube and borosilicate measuring cone The measuring units RA 65 and FA 65 are based on the variable area float principle. In pipelines the RA 65 is installed by means of pipe unions and the FA 65 is mounted between flanges. The borosilicate glass measuring cone is located inside a protection steel tube with an inspection window. VA flow meters RA 65 and FA 65 are most suitable for the flow measurement of transparent fluids and gases. Each unit is customized with a scale specific for the medium to be measured. RA 65 and FA 65 are used e.g. in plant and process engineering. By installation of electrical limit value switches, which are adjustable throughout the entire measuring range, this devices can be used as detectors. By installing an linear displacement sensor an output signal can be generated which is proportional to the height setting of the flow meter. download pdf datasheet

VA Flowmeter RA60/FA60 protective steel tube

VA Flow Meter with protective steel tube and borosilicate measuring cone The measuring units RA 60 and FA 60 are based on the variable area float principle. In pipelines the RA 60 is installed by means of pipe unions and the FA 60 is mounted between flanges. The borosilicate glass measuring cone is located inside a protective steel tube with an inspection window. VA flow meters RA 60 and FA 60 are most suitable for the flow measurement of transparent fluids and gases. Each unit is customized with a scale specific for the medium to be measured. RA 60 and FA 60 are used e.g. in plant and process engineering. By installation of electrical limit value switches, which are adjustable throughout the entire measuring range, this devices can be used as detectors. download pdf datasheet

Short Tube VA Flowmeter SGK

The SGK 1 - 3 flow meters are based on the variable area float principle. They consist of a combination of borosilicate glass measuring cone and float, with a flow scale specific to the process fluid and calibrated to customer requirements. download pdf datasheet

Level Indicator ELD

Ensim ELD liquid level indicators are designed for machine manufactures to control the level of oil or other liquid outside of their vessels / tanks. They can be mounted horizontal or vertical and do not require electrical power. download pdf datasheet

Flap Flowmeter KLA

The KLA Flowmeter uses a flap which is deflected by the flow of the medium. The deflection angle is a direct indication of the flow through the pipe. The flap is gravity-loaded, thus the device can be used for the flow directions left to right, right to left and bottom to top. In the variant KLA-GS the medium be measured is directly visible through a glass in the flow indication unit. download pdf datasheet

Flap Flowmeter KFS spring loaded

The KFS spring loaded measuring device operates largely independent of viscosity and is suitable for indicating the flow rate of water, acids, alkaline solutions and gases. Every device is calibrated to customer requirement and fitted with a product-specific scale. The 50 mm thick ring features a half-round plate that is fastened to a rotating spring-loaded spindle. The angle between flap and ring changes according to the rate of flow, and a breakaway-proof magnetic coupling transfers the movement to an external pointer. download pdf datasheet

Dynamic Flap flow sensor w display - liquids

ME Series Dynamic Flap flow sensor with display for liquids