Multi Component Mixing

SKU: Multimixer

Manufacturer: Centec

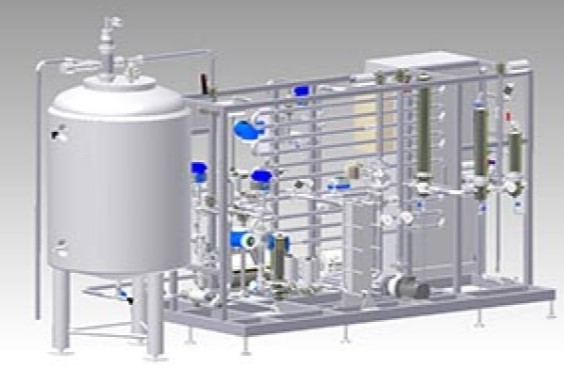

MultiMixer

Application

The MultiMixer is used for the continuous mixing of several streams of liquid products, e. g. deaerated water, syrup and flavours. Since the number of blending channels can be adapted to individual needs, the skid provides a high degree of flexibility for the production of different products (brands).

Description

In multi component mixing different liquid or powder products are blended. The components to be mixed can be supplied from large storage tanks via supply lines or from vessels located on the skid. Mass flows and concentrations are permanently measured in the process and adjusted by ratio controllers. Therefore, the system is equipped with high precision flow meters and in-line sensors made by Centec. Centec have decades of experience in the development and manufacturing of own precision instruments. Frequently, the MultiMixer is also used for carbonation. In this case the skid contains a specifically designed Vortex-Venturi injector that feeds carbon dioxide in a very large number of very fine bubbles directly into the product stream. With the Centec mixing technology low-oxygen dosing of concentrates is possible. Based on the in-line measurements, the product steams and the carbon dioxide flow are instantly and fully automatically monitored and adjusted. Thus, repeatable results and minimum product losses are guaranteed. The modular design of the process unit allows for easy expansion, e. g. for mixing with deaerated water or for pasteurization of the finished product.

- High precision in-line sensor technology for process control

- Excellent accuracy and minimum product losses

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | 10 - 1.500 hl/h |

| Dosing Range Original Gravity | 7 - 20 °P |

| Dosing Accuracy Original Gravity | ± 0,05 °P |

| Dosing Range Alcohol | 0 - 10 Vol. % |

| Dosing Accuracy Alcohol | ± 0,03 Vol. % |

| Dosing Range Brix | 0 - 85 °Brix (80 - 120 % Diet) |

| Dosing Accuracy Brix | ± 0,03 °Brix (± 1 % Diet) |

| Dosing Range CO2 | 0,5 - 10 g/l |

| Dosing Accuracy CO2 | ± 0,1 g/l (on request ± 0,05 g/l) |

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Options | different automation levels; remote maintenance access; in-line measurement of e. g. alcohol, Brix, O2, CO2; water deaeration; carbonation/nitrogenation; pasteurization; buffer tank; cooling |