Recovery of Beer from Yeast

SKU: Yeast Recycler

Manufacturer: Centec

Application

The Yeast Recycler is used for recovering beer from waste or surplus yeast. Beer recovery allows the brewery to reduce wastewater and to obtain two valuable products: Beer and yeast. While the beer can be returned back to the brewing process, the yeast can be sold as animal feed or as food supplement.

Description

For beer recovery with the Yeast Recycler well proven cross-flow technology with robust ceramic membranes is used. The modular design is applicable for all brewery sizes. The recovered filtrate is free of yeast and takes up a minimum of oxygen. Recovered beer can be blended back into the brewing process at a ratio of up to 5 % without negatively influencing the quality of the final product. By adding small amounts of water to the waste yeast, beer recovery is optimized by a wash out effect (diafiltration). The advantage of diafiltration is a higher recovery rate. The O2 content can be monitored by high precision optical OXYTRANS sensors made by Centec. Centec have decades of experience in the development and manufacturing of own precision instruments for O2 control. The Yeast Recycler is highly standardized resulting in low capital costs, a short amortization period and fast pay-back. Furthermore, it can easily be expanded by adding other Centec systems, e. g. for water deaeration and for blending.

- Excellent quality of recovered beer

- Long life ceramic membranes

- Customized modular design with a standard PLC

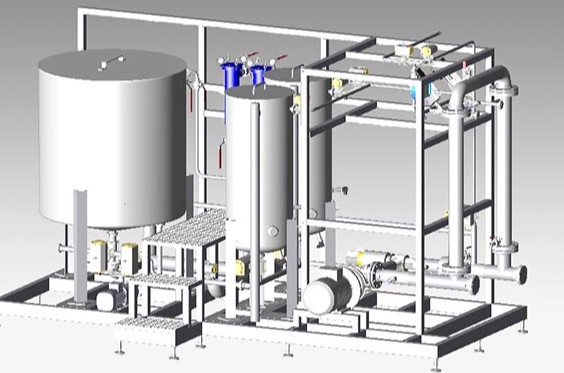

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | 50 - 1.000 hl per day waste/surplus yeast |

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Options | in-line O2 measurement; turbidity measurement; original gravity measurement; water deaeration; blending |